KA

Kunal Aglave

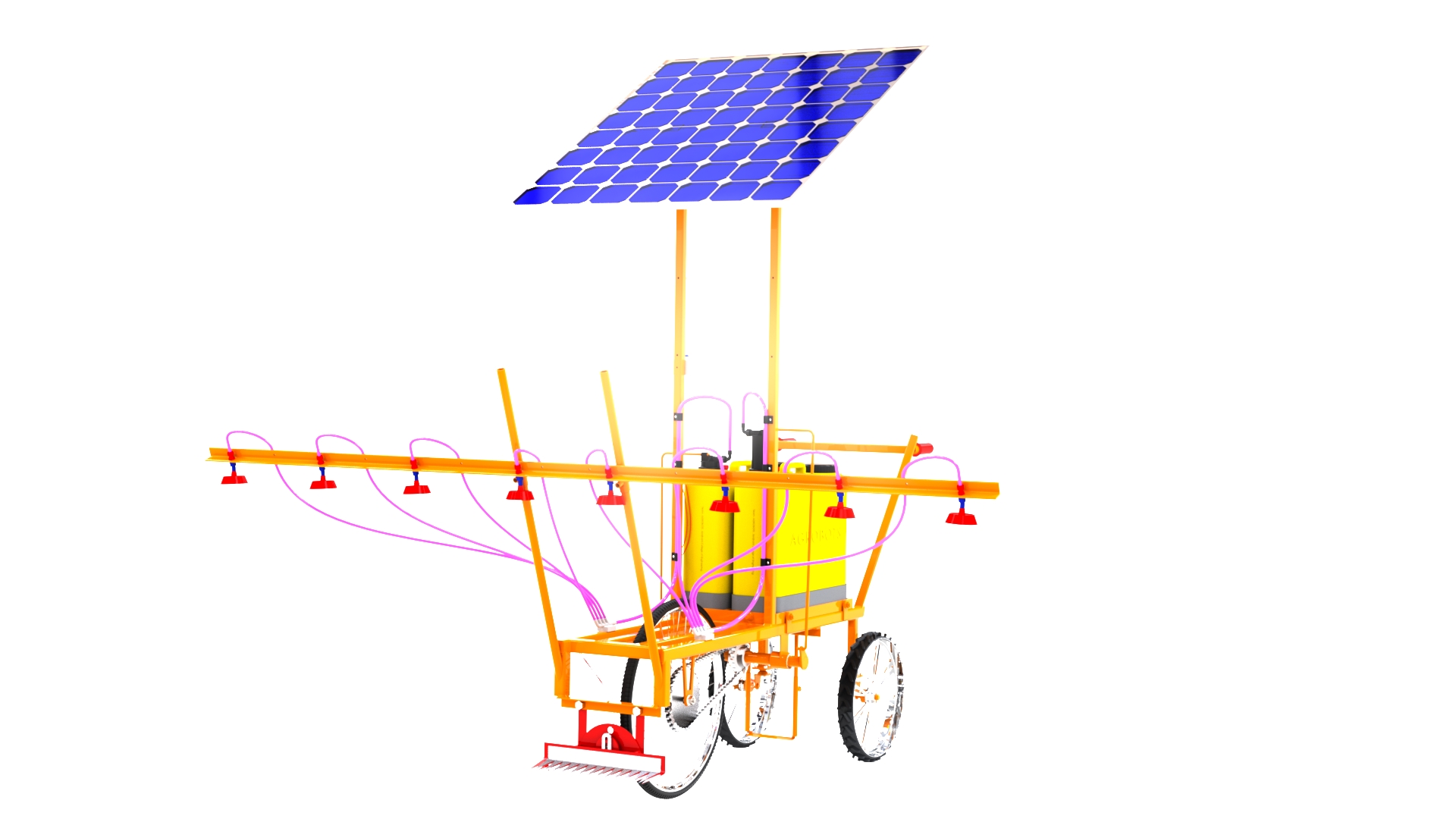

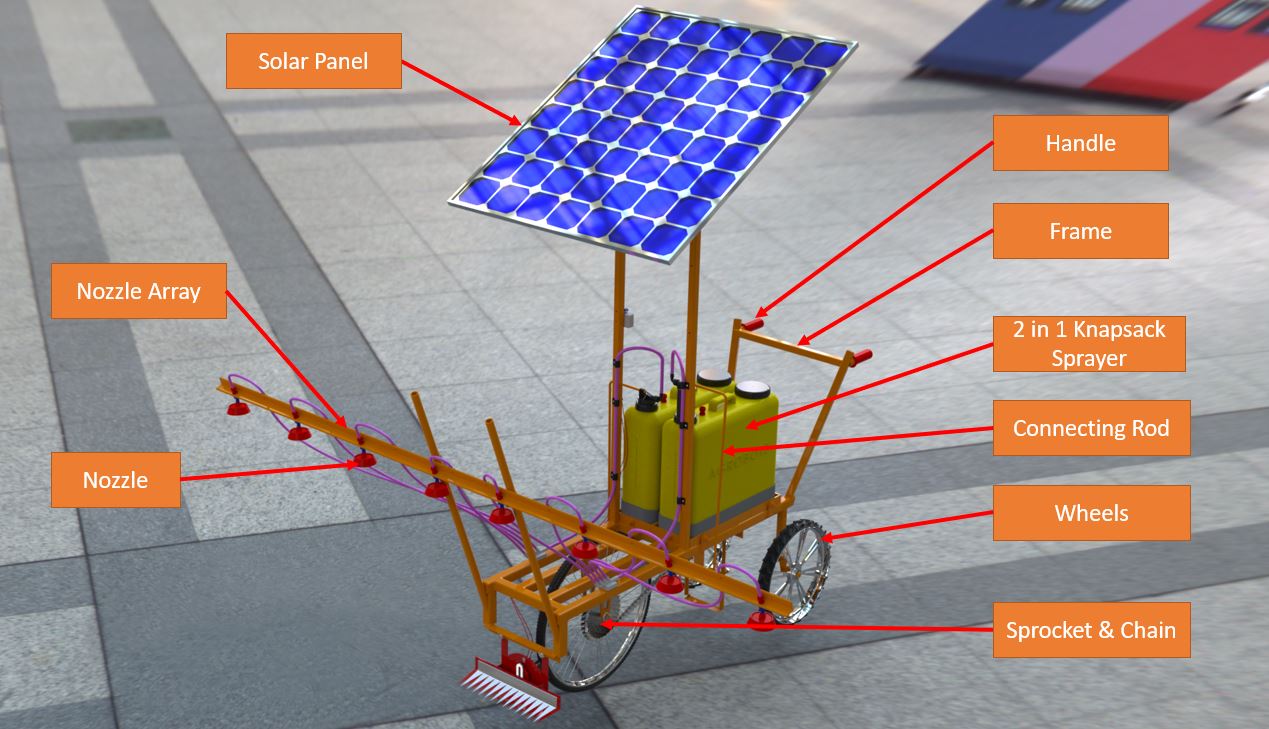

Multi Nozzle Pesticide Sprayer for Agriculture

An Easy and Cost Effective Way to Spray Pesticides

Inde

PROJECT TIMELINE

INTRODUCTION: This project is created to solve the problem of traditional and inefficient spraying methods adopted by farmers. The fertilizer sprayer used by 60 to 70% farmers in India is the “Backpack Knapsack” Fertilizer sprayer. They need to carry it on their back and then cranking it by hand. This type of pumps can’t create high pressure. This may cause many plants to get missed from the spray. Because only one nozzle is there and the operator needs to move the nozzle over each and every plant. One person can cover 2 to 3-acre area in one day. As efforts are required and continuous cranking by single hand causes serious pain in the hand of operator. He also needs to balance himself with the weight of the sprayer and Pesticides. In muddy area it’s difficult to maintain balance as, operator can slip in muddy areas.

Our solution tries to solve above issues so that efforts of farmer gets reduced and time is also saved. We have used manual as well as solar power to operate our product. The manual operation can be helpful, when there is cloudy climate and low sunlight is available. When sunlight is there, we can use solar as well as manual power also. We have designed product in such a way that it can operate on both the types of energy and single type of energy also.

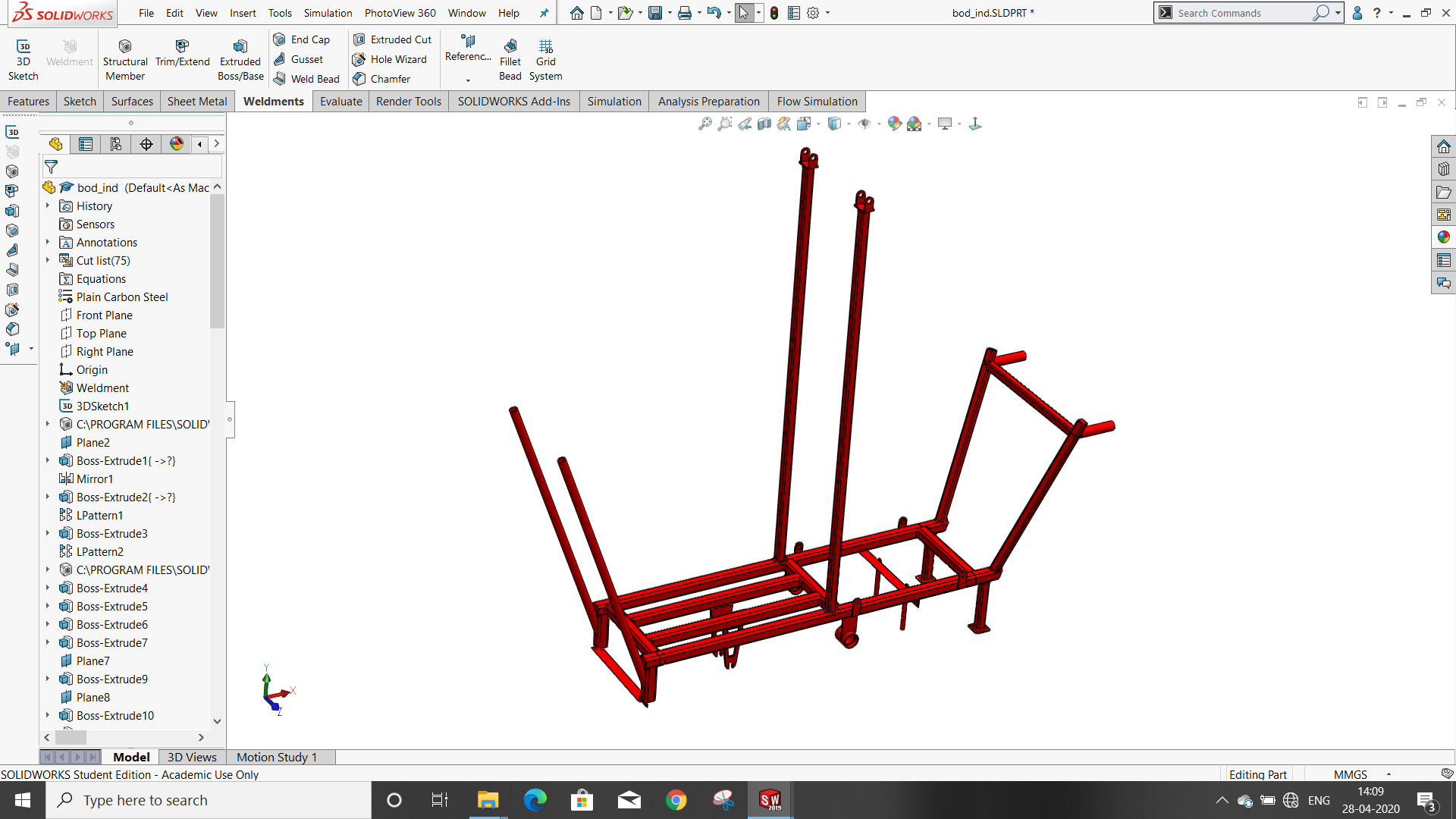

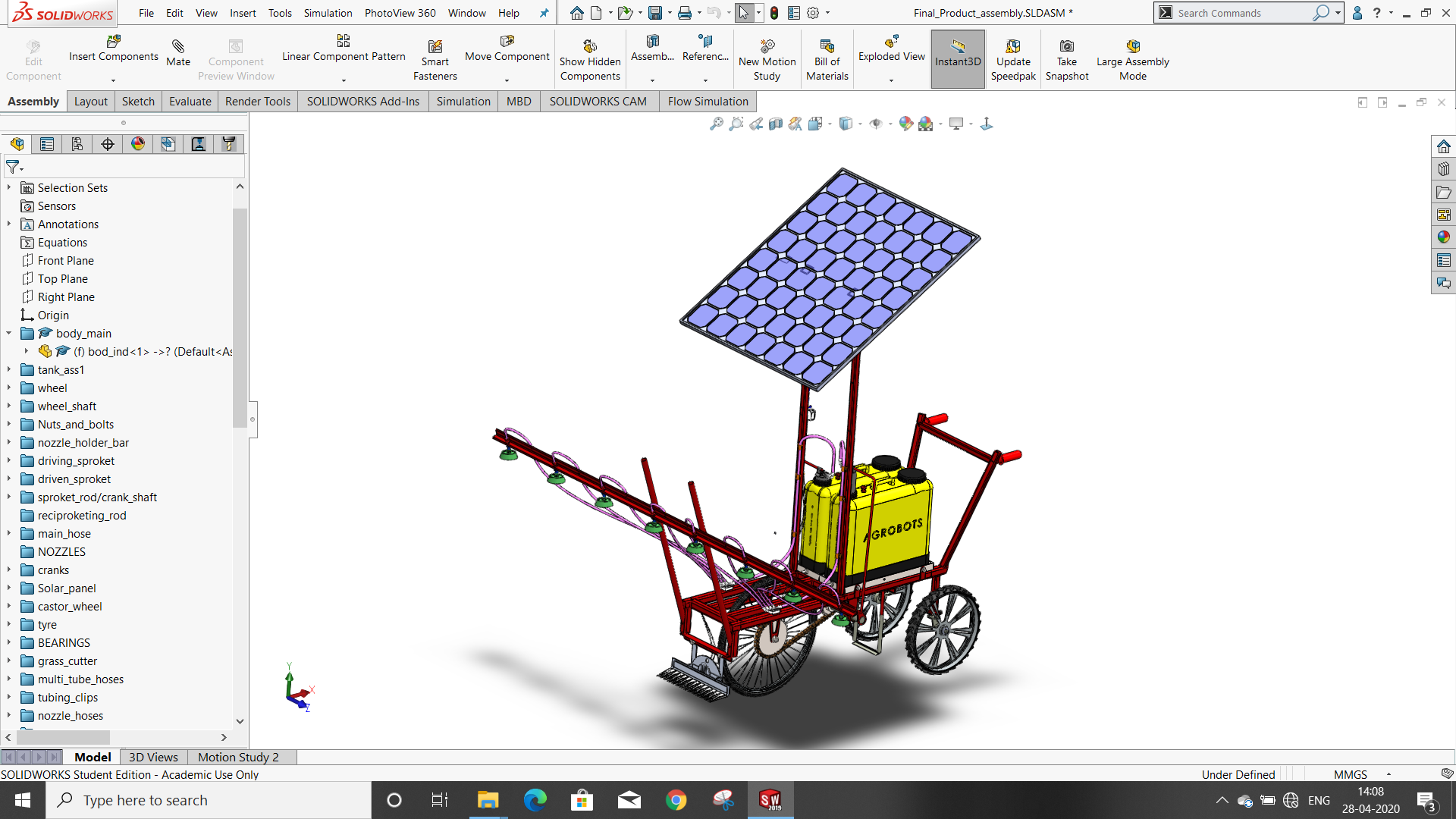

DETAILED IDEA: We tried to use mechanism of bicycle to make our project, as it is available everywhere. It can be manufactures in villages also using some basic tools. One cycle wheel is used on which one driving sprocket is fixed. The driving sprocket is connected to driven sprocket using chain. The driven sprocket is attached to crankshaft. On crankshaft, two cranks are mounted. The cranks give reciprocating motion to the compressors via the connecting rods. As soon as the piston of compressor starts to reciprocate, it creates a positive pressure and starts pumping and compressing the fluid and spraying starts. The operator only needs to steer the sprayer from the field.

WORKING PRINCIPLE: The machine operates on cycle wheel and solar power. Both the powers can be used simultaneously. When the operator steers the sprayer, he needs to apply some nominal force to move the sprayer. The wheel gets rotated. The driving sprocket fixed on wheel rotates the driven sprocket. Driven sprocket is fixed on crankshaft. Two cranks are mounted on both the sides of crankshaft. When the crankshaft rotates, it gives rotatory motion to cranks and cranks provides reciprocating motion to the compressor cylinders via connecting rods. The reciprocating motion to the cylinders creates a positive pressure. The two cylinders uses non return valves to generate the pressure. The pressurized fertilizer solution is then supplied to nozzles via tubes.

Compressor Mechanism: It is having two cylinders. One act as a storage chamber as well as piston. 2nd cylinder is used as a cylinder for suction. There is a ball type non return valve at the bottom of compressor cylinder, which only allows the fluid to enter inside the cylinder. During the suction stroke, the fluid is taken in to cylinder via this non-return valve. The piston also has a non-return valve acting similar to the cylinders non return valve. But gets activated in apposite to suction valve. When valve in suction cylinder is on during suction, the piston valve is closed. During compression, its apposite to suction. This allows the positive pressure to get built up. Due to the use of ball valve, energy required is also less.

Due to very small pores available on nozzle, the fluid gets atomized due high pressure. This allows uniform spraying of fertilizer and high velocity. We used as array of nozzles to increase the spraying area. The height of the nozzles can be adjusted by losing and tightening two nuts only.

There is a 120-watt solar panel attached to the sprayer. The water pump and batteries are inbuilt in the sprayer. When sunlight is available, these motors will take the load of compressor and reduce the force required to steer the sprayer. Also, pressure of the pump is high than reciprocating compressor. Whenever there is cloudy weather, solar panels cannot be used as power source. So manual power is another option for it. When sunlight is available both powers can be combined to get high pressure to allow the use of extra nozzles.

Novelty of the project: There were manually operated sprayers were available in the market. They are of two types – 1) Powered by manual force & 2) Powered by batter. But they both needed to be carried over back of the operator. This is inefficient way of spraying pesticides. There are many solutions available with modern technologies. But every farmer can adopt those expensive sprayers like tractor operated boom sprayers or special purpose sprayers. One farmer tried to mount the manual sprayers on bicycle and powered it from pedal. But it was inconvenient to handle. So, we done research and worked on improving that model. We designed a frame to hold two tanks to double the capacity. Also added multiple nozzles to increase spraying area. We used the 2 in one battery operated pups as a tank for our sprayer. Which comes with manual compressor and also battery-operated compressor. The batter and electric compressors are inbuilt with the pump. So, did not need extra elements. Batteries can be charged from solar power.

Further Improvements: 1) The facility to adjust the height of the wheels for making it able to work with any crop of any height. 2)Improvement of overall design etc.

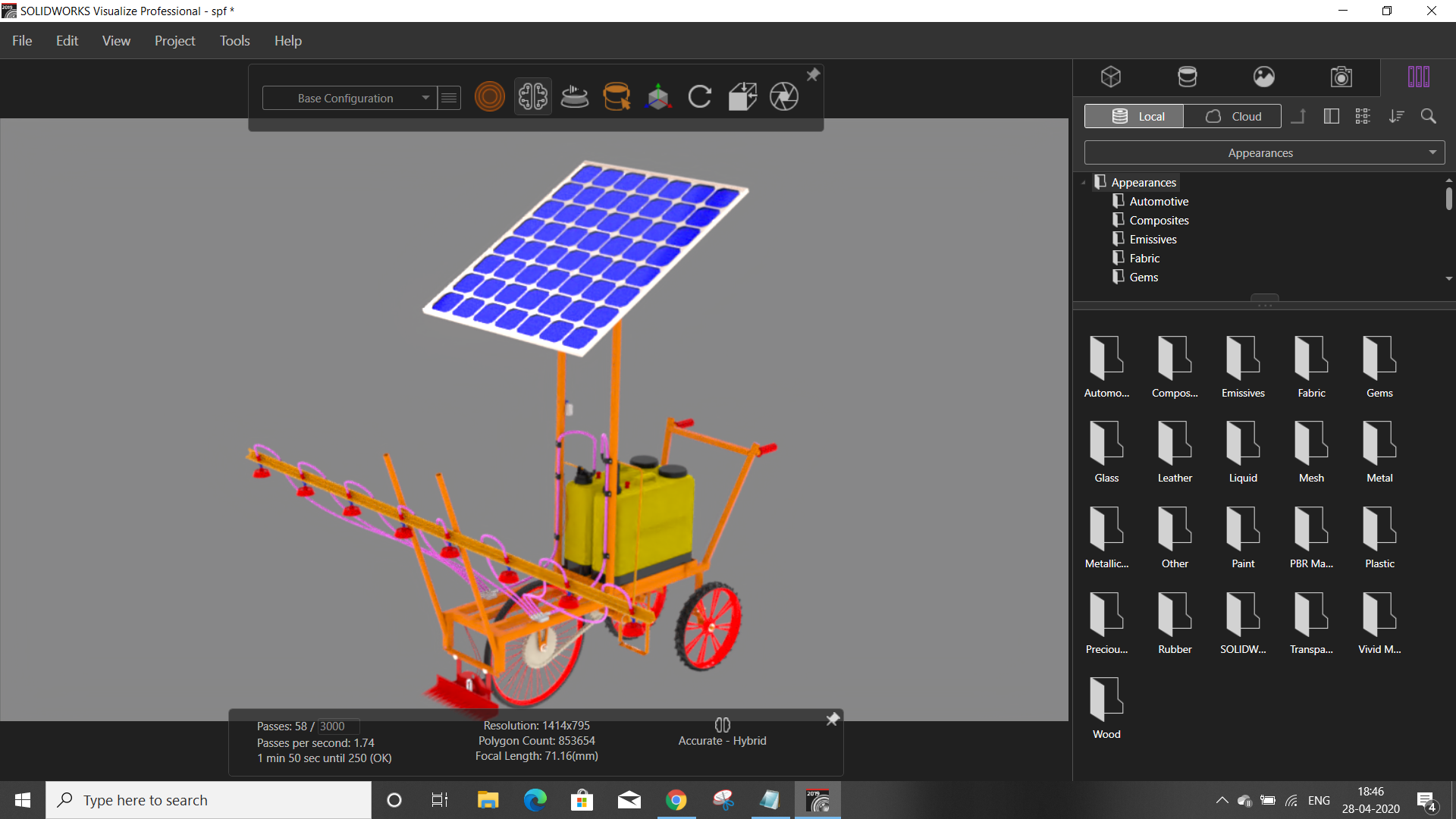

Use of Software: We used Solidworks 2019 for Making the 3D Model of our Product. We used Weldmets, Routing functionality of solidworks. Also used simulation tools for stress analysis and flow simulation. Renderings are done using Solidworks Visualize Professional.

Découvrez l'équipe

Auteurs du projet

Découvrez les logiciels

logiciels utilisés

Project Timeline

This is our project with which we had participated in AAKRUTI 2019. Now we are again participating in project of the year 2020 with the same project. This product was designed by considering the difficulties faced by many farmers. Many farmers use regular backpack sprayer for spraying pesticides on crops. But it is very inefficient way. Buying the expensive sprayers is not affordable to everyone. In the market tractor operated or engine operated sprayers are available. But they are very costlier. So, we decided to make a low cost sprayer which should have minimal operating cost. It should use renewable power for its operation.

About the project.