PL

Projects Legacy

PROJECT TIMELINE

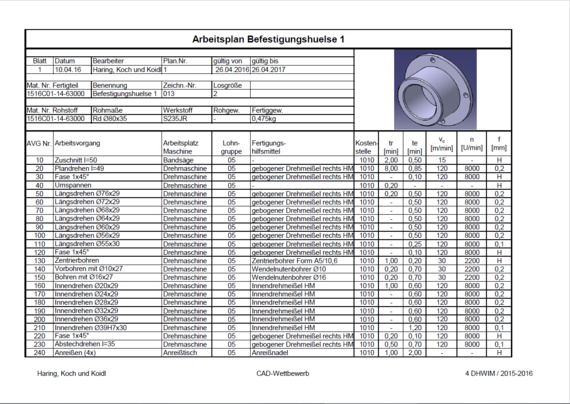

My team consists of Stefanie Haring, Gregor Koch and Thomas Koidl. We are currently attending a higher technical college (Höhere technische Bundes Lehr- und Versuchsanstalt BULME Graz-Gösting Dislozierung Deutschlandsberg im Zweig Wirtschaftsingenieurwesen und Maschinenbau) in Austria.

We would like to Show our Project to the world, because we developed the whole Project on our own and it was our idea to do this. If you like our Project, we ask you to vote for it for the Poty2016. Thank you!

You can find our Video on YouTube: https://www.youtube.com/watch?v=PZZk0WUYq2k

Es ist auch ein deutsches Video auf Youtube verfügbar:https://www.youtube.com/watch?v=a12QHtTTBYI

Dort finden Sie auch eine deutsche Produktbeschreibung.

This is our product description:

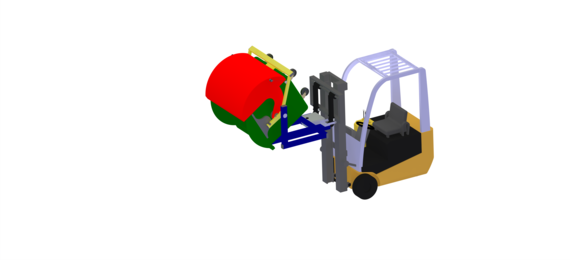

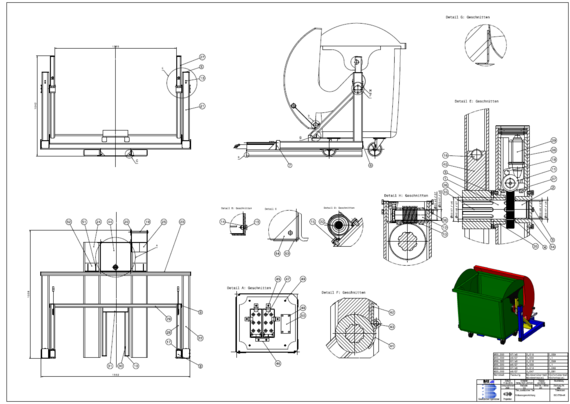

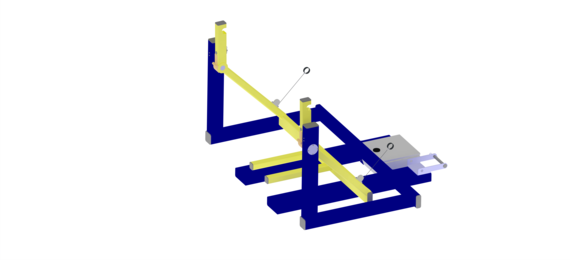

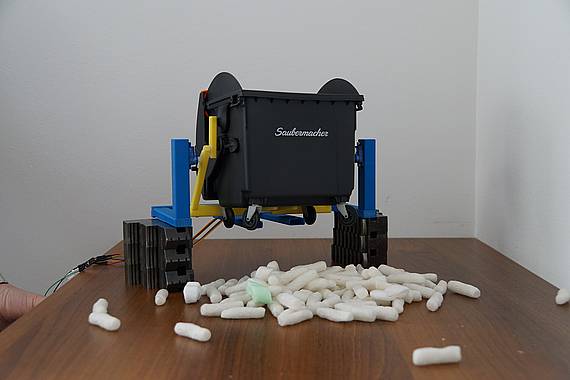

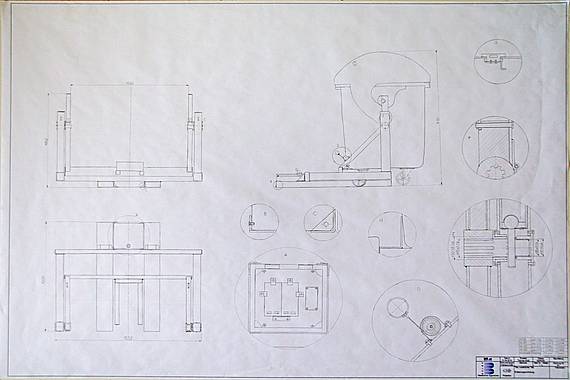

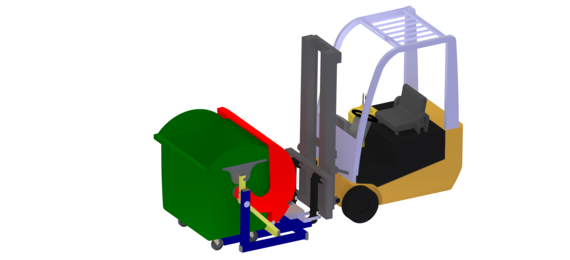

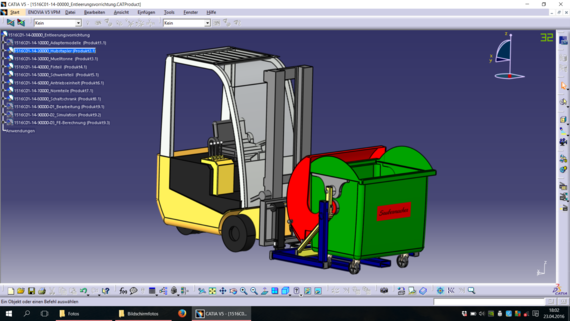

Our Project was to develop a device which is used to empty large dustbins into a dumpster. The device has to be attached to a forklift to be used.

Key data: powered by electricity

Remote controlled

Safety installations

Up to 600kg

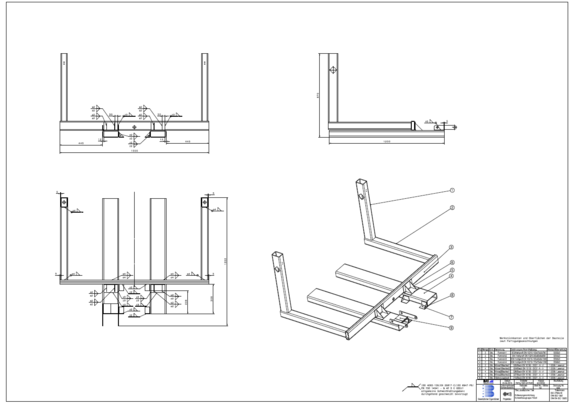

Dimensions 1338x1552x1042 [mm] (length x width x height)

More detailed description of our product:

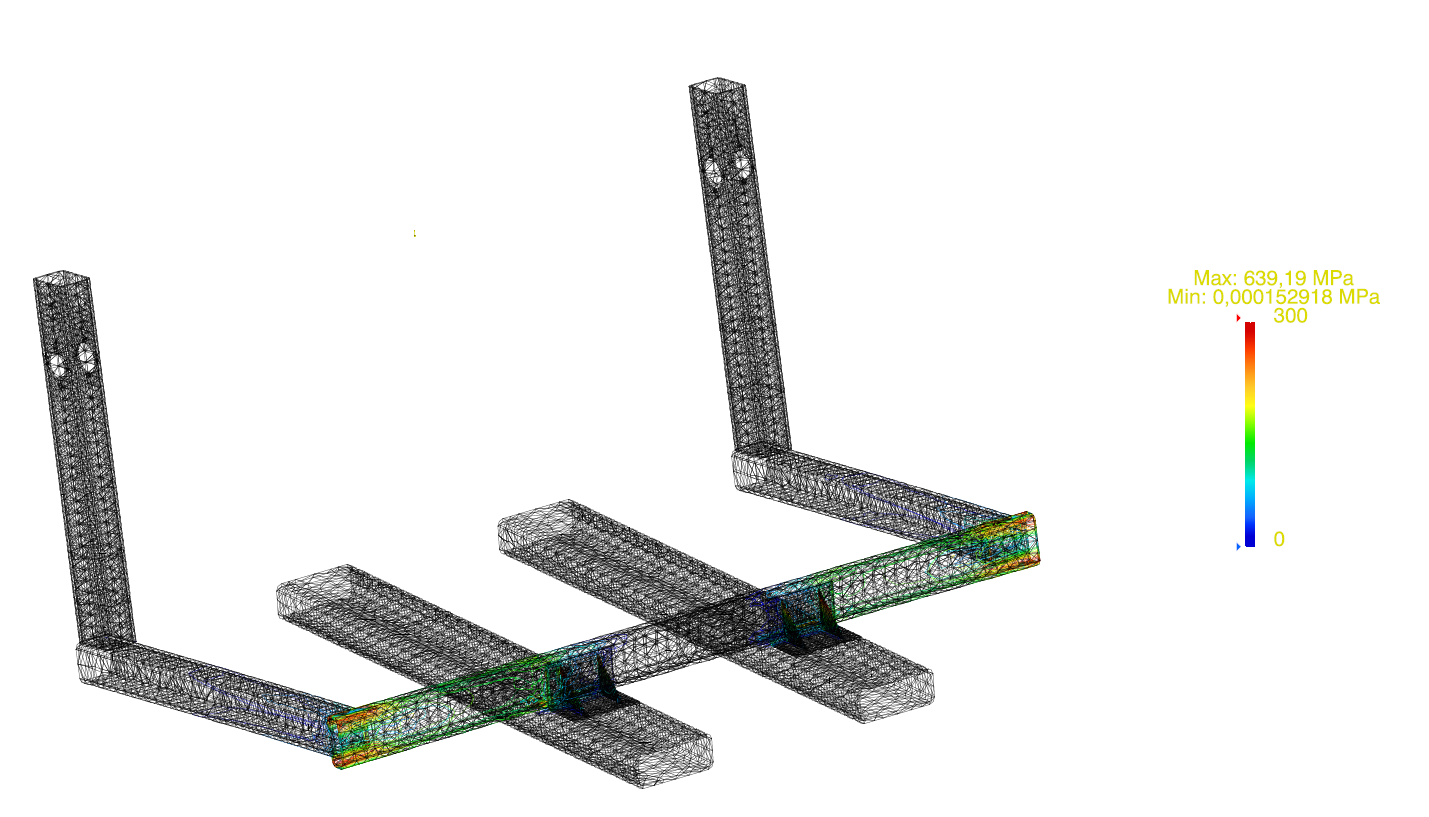

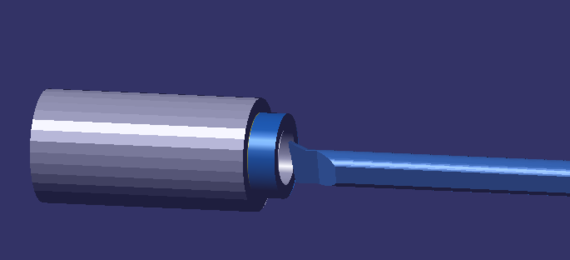

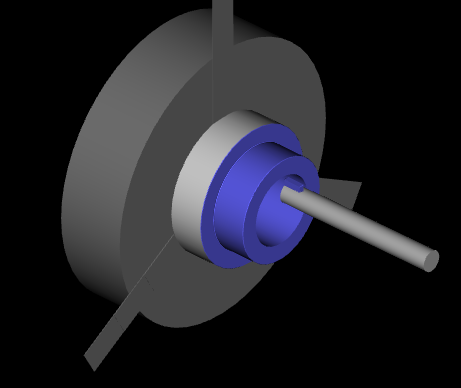

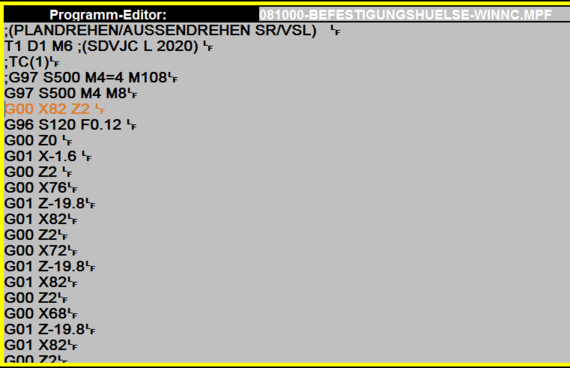

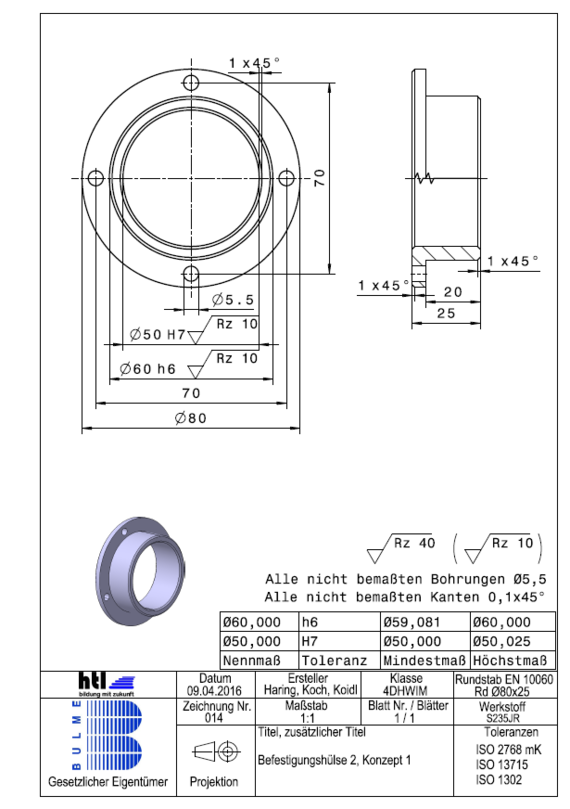

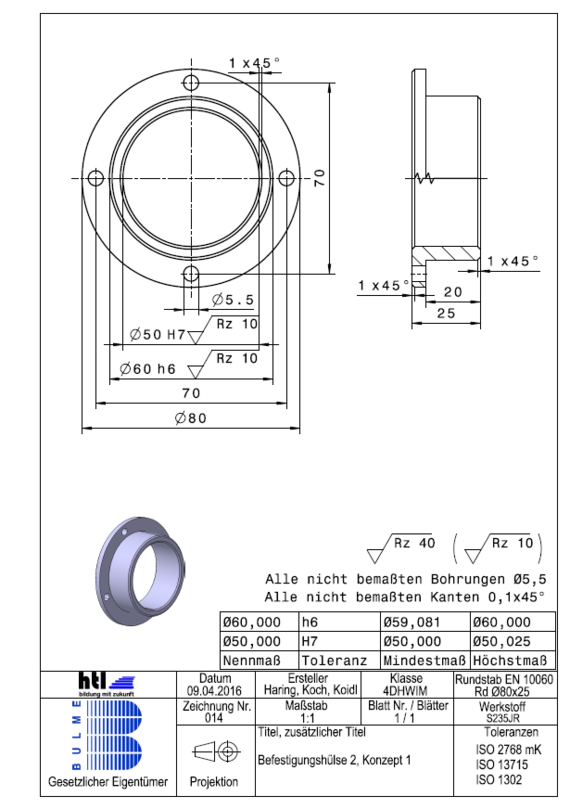

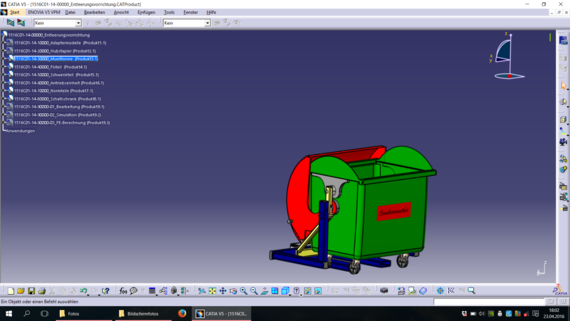

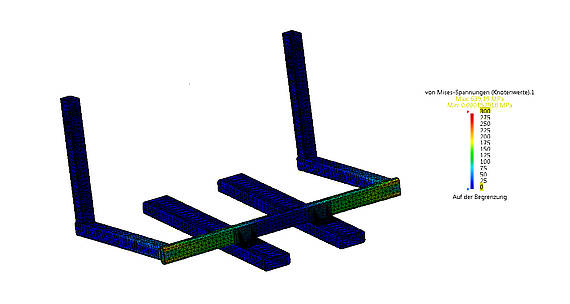

Our device can be stored on a pallet. When you use the device to empty a large dustbin, you have to pick up the device with a forklift. The operator has to secure the device with a bolt to prevent it from sliding off of the forklift. Afterwards the operator drives the forklift to the dustbin, and has to manually push the dustbin into the device. In order to do this, he has to lower a special frame beforehand. When the dustbin is in place, he puts this frame back up and secures it with a bolt. The lid must be opened, and is held in this opened position by a cable. If the operator as completed all these tasks, the dustbin is ready to be emptied. The operator drives the forklift to the container and lifts the forks to the necessary height. Via remote control he starts the tilting movement. An electric motor in one of the frames is connected to a worm gearbox, which transmits the rotation and provides the required torque. The batteries in our cabinet power the two electric motors, and everything is controlled by a microcontroller. There are sensors, which detect when the dustbin has reached its maximum tilt and stop the tilting movement. The operator presses the second button on the remote control and the dustbin is brought back into its normal position again.

Now the empty dustbin can be pulled out of the device and is ready for a refill. The device can be stored on a pallet, so that the forklift can be used as usual in between the emptying-processes. The remote control can be stored on the device.

Découvrez l'équipe

Auteurs du projet

Découvrez les logiciels

logiciels utilisés

Check my new project